Maintenance Products

Help your bearing achieve its maximum service life

Every bearing has a pre-calculated service life. However, research has shown that, for various reasons, not every bearing achieves it. Important stages which have a major impact on a bearing service life can be recognised during the bearing’s lifecycle. These stages are mounting, lubrication, alignment, basic condition monitoring and dismounting. The stages in a bearing life cycle are extremely important for achieving the maximum service life of the bearing. By applying the right maintenance practices and using the correct tools, you can considerably extend your bearing’s service life and increase plant productivity and efficiency.

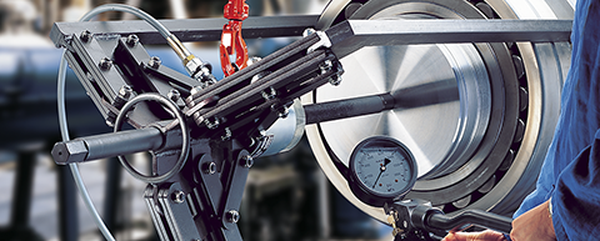

1) Hydraulic tools for mounting and dismounting

Mounting

Around 16% of all premature bearing failures are a result of poor fitting or using incorrect mounting techniques. Individual applications may require mechanical, heat or hydraulic mounting methods for correct and efficient bearing mounting.

Dismounting

When dismounting bearings, care must be taken not to damage other machine components, such as the shaft or housing, as damage can compromise the machine’s efficiency and lifetime. Bearings are sometimes dismounted to maintain or replace other components of the machine.

A) Hydraulic Pumps and Oil Injectors

a) Hydraulic pumps Hydraulic pump 50 MPa

50 MPa - (7 250 psi)

The TMJL 50 pump is mainly intended for use on the low pressure side of SKF OK couplings, but is also suitable for applications where a maximum pressure of 50 MPa (7 250 psi) is required.

The pump is supplied with a 3 000 mm (118 in) long high pressure hose with quick connect coupling and mating nipple. It is filled with SKF mounting fluid LHMF 300 and is supplied with an extra litre of fluid.

b) Hydraulic pump 100 MPa (14500 psi)

100 MPa - (14 500 psi)

The 729124 pump is suitable for use with hydraulic nuts (smaller than or equal to HMV 54E) and for mounting and dismounting bearings or components where a maximum pressure of 100 MPa (14 500 psi) is required.

The pump is supplied with 1 500 mm (59 in.) pressure hose, quick connect coupling and mating nipple and pressure gauge.

c) Hydraulic pump with large oil container 100 MPa

Large oil container 100 MPa - (14 500 psi)

The TMJL 100 pump is suitable for use with hydraulic nuts (smaller than or equal to HMV 92E) and for mounting and dismounting bearings or components where a maximum pressure of 100 MPa (14 500 psi) is required.

The pump is supplied with 3 000 mm (118 in) pressure hose, quick connect coupling and mating nipple, and pressure gauge. The pump is filled with SKF mounting fluid LHMF 300 and is supplied with an extra litre of fluid.

d) Hydraulic pump 150 MPa

150 MPa - (21 750 psi)

The 728619 E is a two-stage pump suitable for use with SKF Supergrip bolts and for the mounting and dismounting of bearings or components where a maximum pressure of 150 MPa (21 750 psi) is required.

The pump is supplied with a 3 000 mm (118 in.) pressure hose, quick connect coupling and mating nipple and pressure gauge.

e) Oil injectors

300 and 400 MPa (43 500 and 58 000 psi)

The 226400 series oil injectors have a varied usage when applying the SKF oil injection method. For mounting and dismounting bearings, couplings, railway wheels, gear wheels, fly wheels, ship propellers and so on. The injector is supplied with an oil reservoir in a compact carrying case.

For applications where 400 MPa (58 000 psi) is required a special model is available: 226400/400 MPa. The injector can be mounted directly onto the work piece or connected to an adapter block to make it a floor standing model making it easy to connect pressure gauges and high pressure pipes.

f) Oil injectors kits

300 and 400 MPa - (43 500 and 58 000 psi)

The oil injection kits contain the oil injector 226400 complete with high pressure pipe, pressure gauge, adapter block and a range of connection nipples all packed together in a sturdy plastic carrying case.

- Complete high–pressure kits, including oil injector, pressure gauge, 2,0 m high–pressure pipe and a range of connection nipples.

- Oil container capacity 200 cm³ (12.2 in.³)

g) Air-driven pumps and oil injectors

30, 150, 300 and 400 MPa (4 350, 21 750, 43 500 and 58 000 psi)

The THAP E air-driven pumps and oil injectors are available in four different pressure versions. They are used for mounting and dismounting OK couplings, for dismounting large pressure joints such as bearings, flywheels, couplings, railway wheels and in many similar applications.

The pumps consist of a high pressure hydraulic pump, driven by an air piston. The units are supplied in a sturdy case including oil suction and return hoses with quick connect couplings. The air driven pumps can also be supplied in complete sets which consists of pump, pressure gauge, high pressure pipe and connection nipples.

B) Pressures gauges

100 to 400 MPa (14 500 to 58 000 psi)

SKF pressure gauges are designed to fit SKF hydraulic pumps and oil injectors. The gauges are all liquid filled and/or equipped with a restriction screw in order to absorb any sudden pressure drop thereby preventing damage. Safety glass and blowout discs are standard for all gauges and all have dual scales (MPa/psi)..

Digital oil pressure gauge

The Digital oil pressure gauge, THGD 100, is used to accurately measure the hydraulic pressure when mounting bearings using the SKF Drive-up Method. The gauge is also suitable for other applications where the pressure has to be determined with high accuracy, up to pressures of 100 MPa (15 000 psi).

C) Hydraulic nuts

Easy application of high drive-up forces

Mounting bearings on tapered seatings can be a difficult and time-consuming job. Using an SKF Hydraulic Nut facilitates easy and quick application of the high drive-up forces required for mounting bearings. Dismounting bearings mounted on either adapter or withdrawal sleeves is also often a difficult and time-consuming job. These problems can be reduced with the use of an SKF Hydraulic Nut.

Oil is pumped into the nut and the piston is pushed out with a force, which is sufficient to free the sleeve. All SKF HMV ..E nuts are supplied with a quick connection coupling to fit the SKF hydraulic pumps.

D) OK Coupling mounting and dismounting kits

TMHK 35 Catalogue text - Connection nipples

Suitable for coupling size OKC 45-OKC 90

Contents

1 x 226400 Injector with spares

1 x 226402 Adapter block

1 x 228027 E Nipple

1 x 227958A Pressure pipe (for OKC 80 and 90)

1 x 728017 A/2000 High pressure pipe (for OKC 45-75)

Tools and storage case

Weight 12 kg

TMHK 36

Suitable for coupling size OKC 100-OKC 170, OKCS 178 -OKCS 360

Contents

1 x 226400 Injector with spares

1 x TMJL 50 Hydraulic pump

Tools and storage case

Weight 19 kg

E) Hydraulic tool accessories

High-pressure pipes

The range of SKF High-pressure Pipes covers most applications where there is a requirement to transfer oil at high pressure. They consist of a steel pipe with a steel ball fitted to both ends. Two swivelling connection nipples press these balls against the seating of the connecting hole and thus sealing against oil leakage.

Wide range of pipes

All pipes are pressure tested to 100 MPa

(14 500 psi) over recommended working pressure

Special lengths (up to 4 000 mm / 157 in) made on request

Flexible high-pressure hoses

Maximum working pressure up to 150 MPa (21 750 psi)

Flexible high-pressure hoses The SKF Flexible High-pressure Hoses are designed to be used together with the quick connect coupling 729831 A and nipple 729832 A on the range of SKF hydraulic pumps.

Feeler gauges

For accurate bearing clearance measurement

Feeler gauges 729865 series Feeler gauges 729865 series SKF Feeler Gauges are designed to measure the internal clearance when adjusting spherical roller bearings. Two types are available, one with 13 blades of 100 mm (4 in) length and the other with 29 blades of 200 mm (8 in) length.

High accuracy of measurement

729865 A is supplied with protective plastic cover

729865 B is supplied with protective steel cage

Quick connecting coupling and nipples

For easy pressure hose connection

Quick connecting coupling and nipples One coupling and two different nipples are available to connect SKF hydraulic pumps to the work piece. When nipples with other thread types are required, select an additional SKF nipple from the range to make the connection. Nipple 729832 A is supplied standard with all SKF Hydraulic Nuts HMV E series.

Plugs for oil ducts and vent holes

Up to 400 MPa (58 000 psi)

Plugs for oil ducts and vent holes SKF plugs have been designed to seal off oil connections at a maximum pressure of 400 MPa (58 000 psi).

Connection nipples

SKF Connection Nipples SKF provides a wide range of connection nipples covering many different thread combinations and sizes.

They are used as adapters to enable pipes and hoses to be connected to different thread sizes.

Extension pipes with connecting nipples

Catering for adapter and withdrawal sleeve applications

Extension pipes with connecting nipples M4 extension pipe with connection nipple

Used to extend a high pressure pipe with a G1/4 nipple (e.g. 227957 A) when the sleeve connection hole has a M4 thread. The extension pipe and connection nipple should be ordered as separate items.

Adapter block

Adapter block 226402 The adapter block 226402 consists of a cast steel block to which a pressure gauge and high pressure pipe can be connected. It comes with a floor support and a 90 degree connection nipple for the oil reservoir.

Mounting fluid

For easy and quick bearing mounting

Mounting fluid LHMF 300 The SKF Mounting Fluid LHMF 300 is suitable for use with SKF hydraulic equipment, including hydraulic pumps, HMV ..E nuts and oil injection tools. The LHMF 300 contains anti corrosives which are non aggressive to seal materials such as nitrile rubber, perbunan, leather and chrome leather, PTFE, and so on.

Dismounting fluid

Dismounting fluid LHDF 900 The SKF Dismounting Fluid LHDF 900 is suitable for use with SKF hydraulic equipment, including hydraulic pumps, HMV nuts and oil injection tools. The product contains anti corrosives which are non aggressive to seal materials such as nitrile rubber, perbunan, leather and chrome leather, PTFE, etc.

SensorMount indicator

SKF SensorMount indicator TMEM 1500 The SensorMount Indicator TMEM 1500 provides a direct reading of the fit of a SensorMount bearing mounted on a tapered seating. The SensorMount indicator is only compatible with SKF bearings, which are fitted with the SensorMount sensor. These bearings from SKF have designation suffixes ZE, ZEB, or ZEV, e.g. ZE 241/500 ECAK30/W33. The SensorMount indicator provides a numeric value, which guides the user in achieving a reliable bearing fit.SKF bearings fitted with the SensorMount system can also be mounted on adapter sleeves, withdrawal sleeves and hollow shafts. The material composition of the shaft has no effect on the proper operation of the SensorMount system.

2) Mechanical tools for mounting and dismounting

Mounting

Around 16% of all premature bearing failures are a result of poor fitting or using incorrect mounting techniques. Individual applications may require mechanical, heat or hydraulic mounting methods for correct and efficient bearing mounting.

Dismounting

When dismounting bearings, care must be taken not to damage other machine components, such as the shaft or housing, as damage can compromise the machine’s efficiency and lifetime. Bearings are sometimes dismounted to maintain or replace other components of the machine.

Mechanical dismounting

Choosing the right puller for the job is critical. The puller type, and its maximum withdrawal capacity are crucial for completing any dismounting job safely and easily. Puller overload can result in breakage of the puller’s arms and/or beam and therefore should be avoided. This breakage can damage the bearing or shaft and can cause personal injury.

A) Bearing fitting tools (mounting)

a) Axial lock nut sockets

Easy mounting and dismounting without nut damage

SKF axial lock nut sockets are designed for safe and easy tightening and loosening of lock nuts. They are used to secure and adjust bearings on tapered journals, adapter sleeves and withdrawal sleeves.

- Demands less space around the bearing arrangement than hook spanners

- Inch connections for power tools or torque wrenches

- TMFS fits nuts of series KM, KMK (metric) and KMF

b) Bearing fitting tool kits

Helps prevent premature bearing failure

Poor fitting, usually using brute force, accounts for 16 % of premature bearing failures. The SKF bearing fitting tool kit TMFT 36 is designed for quick and precise mounting of bearings, while minimising the risk of bearing damage. The right combination of impact ring and sleeve allows effective transmission of mounting force to the bearing ring with the interference fit, minimising the risk of damaging the bearing’s raceways or rolling elements.

c) Combi kit

Multi-purpose kit for quick and easy mounting and dismounting

The SKF Combi Kit TMMK 10-35 is designed for quick and precise mounting of bearings with bore diameters from 10 to 35 mm and for dismounting deep groove ball bearings from shafts, housings and blind housings from the same range. For mounting, a multipurpose fitting tool is included which is suitable for mounting bearings as well as bushings, seal rings, belt pulleys and other similar products.

For dismounting of deep groove ball bearings from blind housings and shafts, the SKF Combi kit contains a unique three armed puller.When dismounting deep groove ball bearings from housings, a combination of this puller, sliding hammer and support rings enables easy removal of bearings.

d) Hook spanners

Exact spanner radius reduces the risk of nut damage

The HN series includes 15 different size hook spanners based on the DIN 1810 standard. The hook spanners are designed for use with SKF KM nuts as well as any other KM nuts conforming to the DIN 981 standard.

Additionally, they are suitable for use with N, AN, KMK, KMFE and KMT as well as nuts manufactured according to the DIN 1804 standard.

e) Adjustable hook spanners

Four sizes for tightening or loosening up to 24 nut sizes

The SKF Adjustable Hook Spanners HNA series facilitate the easy and safe tightening and loosening of KM, KML, N, AN, KMK, KMFE and KMT nuts.

The spanners are made of special hardened steel for durability.

One hook spanner covers several nut sizes, making it suitable for use with many applications.

f) Hook spanners HN SNL series

Easy and quick bearing mounting and dismounting in SNL housings

The hook spanners of HN ../SNL series are especially designed to facilitate easy and quick mounting and dismounting of bearings with tapered bore on adapter sleeve in SKF SNL bearing housings. They are also suitable for tightening and loosening a wide variety of locknuts in both housing and shaft applications.

The HN ../SNL series consists of 16 sizes suitable for nut outer diameter ranging from 38 to 145 mm (1.5 to 5.7 in). The spanners are made of hardened high quality chrome vanadium steel for durability.

g) Impact spanners

High impact forces without nut damage

SKF impact spanners are designed for safe and easy tightening and loosening of locknuts used to secure and adjust larger bearings directly on the shaft or with adapter and withdrawal sleeves.

- Avoids shaft and nut damage

- Safe and user friendly

- Impact applied effectively to the nut

- Suitable for nuts of series KM, HM..T, HML..T, HM 30, HM 31, AN.., N.. and N... (for nut sizes 23 and above)

- Special wide impact face

h) Lock nut spanners

For achieving the correct radial clearance

The TMHN 7 set of lock nut spanners is especially designed for mounting self–aligning ball bearings as well as small spherical roller and CARB® bearings on tapered seatings. Using the TMHN 7 minimises the risk of over–tightening of the lock nut, which can result in removing the bearing’s radial clearance and bearing damage.

- 7 different–sized spanners to fit nut sizes 5 to 11

- Each spanner is equipped with a protractor and is clearly marked with the correct tightening angle for mounting SKF Self aligning ball bearings

- 4 grip points on each spanner giving better and safer grip on the nut

- Reduced risk of damaging bearing by over–tightening

- Suitable for use with lock nuts of the KM series either on shaft or in SNL housings

- Special wide impact face

B) Bearing pullers (dismounting)

KF offers a wide range of bearing pullers for various types of pulls: External, internal and even blind. The range includes mechanical, hydraulic and hydraulically assisted pullers for easy application of high withdrawal forces.

a) External pullers

One of the most common ways to dismount small to medium size bearings is to use a basic mechanical puller. Using an SKF puller helps to safeguard against damage to the bearing or to the bearing seating during dismounting.

SKF jaw pullers allow for easy and safe puller operation.

b) Internal Pullers

Fast and easy bearing dismounting

The SKF TMIP Internal bearing pullers are specially designed for dismounting bearings from housings where the fit is on the outer ring.

SKF designed, the bearing pullers generate optimum puller force with use of spring-operated extractors and a unique designed sliding hammer, with no need for additional tools.

- Easy removal of bearings from housings, decreases the amount of time to dismount the bearing

- Specifically designed to suit bearing bore diameters, making the selection of extractors easy

- High-strength chrome coated engineering steel used in the puller construction provides optimum strength and durability

- Spring operated extractors helps result in easy expansion of the extractor to fit the inner ring

c) Blind housing puller kit

Removes bearing without dismantling machinery

The TMBP 20E is an adapter type puller for dismounting deep groove ball bearings in blind housings (i.e. when accessing the ball bearing is not possible through the outer ring or through the bore) with shaft dimensions between 30 mm and 160 mm. The use of extension rods allows a long reach of up to 583 mm.

- With 6 sets of adaptors, a wide of range of deep groove ball bearings can be dismounted

- New ball adapters are more durable

- Spanner stop function on spindle for easy and safe handling

- Special nose piece helps in minimizing damage to shaft and improves puller stability

- Special nose piece helps in minimizing damage to shaft and improves puller stability

d) Deep groove ball bearing puller

Easy dismounting of bearings in blind housing

The SKF TMIP Internal bearing pullers are specially designed for dismounting bearings from housings where the fit is on the outer ring.

SKF designed, the bearing pullers generate optimum puller force with use of spring-operated extractors and a unique designed sliding hammer, with no need for additional tools.

- The claws are especially designed to facilitate a precise fit in the bearing’s raceways, providing good grip and allowing the application of higher dismounting forces

- Each puller arm is fitted with a spring for easy installation

e) Reversible jaw pullers

Versatile and robust pullers for internal and external pulling jobs

The multi-purpose SKF Reversible Jaw Pullers are suitable for internal and external pulling of bearings and other components, such as gears and pulleys. The standard range of eight pullers can accommodate a wide range of bearing and component sizes. Adding extra versatility to the TMMR..F puller programme, the four largest sizes are also available with extra long arms as a standard option (TMMR ….XL). The extra long arms help to dismount bearings and components placed far from the shaft end. For more versatility, the extra long arms can be further extended by adding extension pieces.

f) Bearing puller accessories

A range of accessories has been developed to further facilitate the ease of use of the SKF puller range.

3) Bearing heaters

A) Heaters for mounting

Around 16% of all premature bearing failures are a result of poor fitting or using incorrect mounting techniques. Individual applications may require mechanical, heat or hydraulic mounting methods for correct and efficient bearing mounting.

a) Electric hot plate

Thermostat controlled bearing heating

The SKF Electric Hot Plate 729659 C, is a professional heating device especially designed for pre-heating small bearings prior to mounting. The temperature of the plate can be adjusted at the turn of a knob to provide a temperature range of between 50 and 200 °C (120 and 390 °F).

- Adjustable temperature range of 50 - 200 °C (120 - 390 °F)

- Protective cover to avoid contamination during heating

b) Portable induction heater

A portable bearing heater weighing only 4,5 kg (10 lb)

The SKF bearing heater TMBH 1 is a portable lightweight heater for heating bearings with an inner diameter ranging from 20 to 100 mm (0.8 to 4 in) and a maximum corresponding weight of 4,5 kg (10 lb). The heater uses a patented method of heating based on high frequency induction, which provides optimised efficiency.

c) Small induction heater

Small induction heating system with high heating capacity of up to 40 kg bearing

The SKF small induction heater TIH 030m combines high heating capacity with portability. The compact lightweight design makes the TIH 030m portable. Placing the induction coil outside the heater's housing allows the heating of bearings weighing up to 40 kg.

The induction heater is equipped with thermal overheating protection to reduce the risk of damage to the induction coil and the electronics. In addition to temperature mode, the TIH 030m is equipped with a time mode for heating components other than bearings. The induction heating system is supplied standard with three yokes and is available in two executions: 230V/50-60Hz and 100-110V/50-60Hz.

d) Medium induction heater

Medium bearing heater with high heating capacity of up to 120 kg bearing

The SKF medium induction heater TIH 100m has the same high standards of efficiency and performance as the smaller heater TIH 030m, combined with increased capacity.

The advanced design of the power electronics allows features of accurate electric current control, cut-outs to avoid overheating, controls on rate of temperature increase, these are as some of the standard features in the TIH...m range.

e) Large induction heater

Large bearing heater with high heating capacity of up to 300 kg bearing

The SKF large induction heater TIH 220m is a reliable and robust induction heater from the SKF TIH...m range suitable for heating bearings up to a maximum weight of 300 kg (660 lbs) and solid components up to a maximum weight of 150 kg (330 lbs).

Advanced design of the power electronics including current and overheating control, combined with user friendly features such as sliding arms and remote control are standard to the TIH...m range.

f) Extra large induction heater

High efficiency, energy saving induction heater with a 1 200 kg bearing heating capacity

The SKF Induction Heater TIH L series are intended for heating large size rolling bearings and

components forming a closed circuit such as housings, gear wheels and couplings.

With advanced power electronics and a dual coil design, the TIH L series can heat large bearings up to 1 200 kg (2 600 lbs), using just 20 kVA of electrical power. This is a power saving of almost 50% compared to traditional induction heaters.

g) Multi-core induction heaters

A unique and flexible heating solution for very large bearings and workpieces

The patent pending, SKF Multi-core Induction Heaters TIH MC series are energy efficient custom-made heating solutions, that can save heating time and potentially reduce CO2 emissions.

- Flexible design, consisting of a number of induction heating cores and coils controlled by a single control and power cabinet.

- Suitable for heating large thin section workpieces, such as railway tyres.

- Depending on workpiece, heating capacities of several tonnes can be realised.

- For components sensitive to uneven induction heating, they allow for a more even temperature gradient across the whole circumference

h) Bearing heater accessories

A range of accessories has been developed to further facilitate the ease of use of the SKF bearing heater range.

B) Heaters for dismounting

Dismounting

When dismounting bearings, care must be taken not to damage other machine components, such as the shaft or housing, as damage can compromise the machine’s efficiency and lifetime. Bearings are sometimes dismounted to maintain or replace other components of the machine.

a) Aluminium heating rings

For regular dismounting of cylindrical roller bearings

The aluminium heating rings are designed for dismounting inner rings of cylindrical roller bearings. They are available for all bearing sizes of the NU, NJ and NUP series, these are bearings without flanges or with only one flange on the inner ring. The rings are available as standard for the following bearing sizes: 204 to 252, 304 to 340, 406 to 430.

b) Adjustable induction heaters

For frequent dismounting of cylindrical roller bearings

The adjustable induction heaters EAZ 80/130 and EAZ 130/170 are used for frequent dismounting of cylindrical bearing inner rings.

Where inner rings are removed infrequently, aluminium heating rings, TMBR series, are also available. For larger cylindrical inner rings normally found in steel mill applications, SKF can supply special EAZ induction heaters.

c) Fixed induction heaters

Quick roll changes with bearing removal within minutes

In light section mills and wire rod mills, four-row cylindrical roller bearings are usually used to take up the roll separating forces. The inner rings of these bearings are mounted with an interference fit on the roll necks. Because of the rapid wear, heavy loads and severe contamination the rolls must be frequently replaced. This inevitably involves dismounting the inner rings and remounting them onto new rolls.

4) Alignment tools

Shaft alignment

Reduce machinery breakdowns by up to 50% and increase your uptime

It’s a fact. Shaft misalignment is responsible for up to 50% of all costs related to rotating machinery breakdowns. Accurately aligning shafts can prevent a large number of machinery breakdowns and reduce unplanned downtime that results in a loss of production. In today’s challenging environment of reducing costs and optimizing assets, the necessity of accurate shaft alignment is now greater than ever.

A) Belt alignment tools TKBA 10 and TKBA 20

Versatile tools for pulley and sprocket alignment

The SKF TKBA 10 and TKBA 20 allow pulleys and sprockets to be aligned on the side face. The unit magnetically attaches to the inside or outside face of almost any belt pulley or chain sprocket and has no small parts or targets that can get lost. A laser line is projected from the transmitter unit to the reflector unit mounted on the opposite pulley.

B) Shaft alignment tools

What can SKF offer?

After extensive consultation with users, SKF has developed a range of easy-to-use shaft alignment tools that are suitable for a majority of alignment tasks.

C) Shims

Shims

For accurate vertical machinery alignment

Accurate machine adjustment is an essential element of any alignment process. SKF single slot pre–cut shims are available in five different dimensions and in ten different thicknesses.

- Made of high quality stainless steel, allowing re–use

- Easy to fit and to remove

- Close tolerances for accurate alignment

- Thickness clearly marked on each shim

- Fully de–burred

- Pre–cut shims are supplied in packs of 10 and complete shim kits