OIL SEALS

Seals have a crucial impact on system performance. Life and reliability of what is often considered a simple component can make all the difference to your products and operations. SKF has more than 100 years of experience in various industries and applications, and is the only company that can support key aspects of the sealing system through its knowledge of bearings, seals, lubrication and associated science and technology. SKF offers expert advice and provides support throughout the life cycle of your sealing system.

A) Automotive seals

SKF is a leading manufacturer of seals for the transportation industry and offers a wide spectrum of advanced sealing solutions for cars, light vehicles, trucks, buses, motor cycles and bicycles.As a specialist in both bearings and seals, SKF is able to combine these products and their functions in high-performance units, providing a unique advantage.We supply seals to OEM’s globally from our manufacturing sites throughout North America, Europe and Asia. Our sales teams are available to support customers locally.

1. Bearing

Rolling resistance is a significant factor in the power losses of vehicles. Seals used in bearings can be a significant contributor due to the friction generated. SKF has addressed this issue with new designs and bearing seals materials which provide reduced friction and longer service life, keeping lubricants in and contaminants out.

a) Clutch release bearing seals

SKF clutch release bearings represent the first truly clutch-compatible bearing with its patented variable contact raceway geometry. This exclusive variable contact design permits maximum speeds at maximum loads, resists wear for longer life, and minimizes noise and vibration.

b) Hub bearing unit seals for light vehicles

As expert in bearing and seals, SKF is uniquely situated to understand the requirements for sealing wheel bearing units for cars and to translate these into advanced solutions.SKF seals use advance materials and sealing lip designs to provide both low friction and excellent contamination exclusion which results in longer service life.An integrated magnetic trigger wheels can optionally be included in the sealing system to provide a signal for ABS.

c) Universal joint seal

The U-joint is a flexible joint which allows the propeller shaft to transmit torque from the gearbox at an angle.

The SKF U-joint seal has several design advantages and makes it possible to reduce maintenance cost. This maintenance free bearing and appropriate snap rings, where SKF produces both bearing cups and crosses to guarantee fitting tolerances between the needle rollers and the inner diameter of the cup. SKF grinds both the inner and outer surfaces of the cups

d) Hub bearing unit seals for heavy duty vehicles

As a major force in the bearings market, SKF is uniquely situated to understand the requirements for sealing wheel bearing units for heavy duty vehicles and to translate these into advanced solutions.

SKF seals use advanced material developments and sealing lip designs to provide both low friction and excellent contamination exclusion which results in long service life.

e) Kingpin seals

The SKF kingpin main benefit is the elimination of the normally frequent lubrication of the steering axle kingpin. An additional consequence might be the possibility to apply sensors for modern steering systems that usually should not reside in the normally applied grease.

The solution is a combined offer of a special kingpin seal and an angular contact spherical plain bearing.

f) Water pump bearing seals

Water pump bearing seals are specifically designed for water pump applications.

The water pump is the heart of the automotive cooling system, typically a belt-driven centrifugal pump. The pump circulates coolant throughout the system while the engine is running. If the drive belt fails, the water pump will not function. It is one of the reasons it’s so important to always check the status of the belt during maintenance.

2. Body Seals

Gas springs are used to assist opening, closing, lifting, lowering and damping, movements, for example to support the tailgate or bonnet of a car. There are also many applications in general industry, for example in office chairs or kitchen cupboards. SKF gas spring seals help to retain oil and pressures of up to 200 bar within a gas spring, optimizing the overall function of the spring.

a) Gas spring seals

Gas springs are devices used to lift and support in automotive and general industrial applications. The function of the seal is critical for the function of the gas spring. SKF gas spring seals enable pressures of up to 200 bar to be durably maintained within the spring, while providing low friction and break-away force.

Benefits :

- Very low loss of force (high pressure retention)

- Very low weight loss

- Low break-away force

- Low static and dynamic friction

- Long service life

- Experience from the market leader

3. Driveline Seals

There is a strong need for continuous development and innovation in the driveline. SKF seals can deliver unparalleled performance over a wide range of operating conditions to reduce power losses and minimize fuel consumption and vehicles emissions. In addition, for automatic transmissions, the gear change performance affects the overall comfort of the vehicle.

a) Axle seals

SKF provides a full range of shaft seals for axle applications. For car and light truck as well as for heavy duty commercial vehicles. In their exposed locations beneath the vehicle, contamination exclusion is key to a long seal life and SKF offers a range of solutions addressing this issue.

Features

- Specially formulated advance elastomeric materials

- Range of hydrodynamic features available

- Radial and axial excluder lips

- Many outer diameter options

- Thermoplastic / rubber thrust bumper

- Thermoplastic shaft guide where needed

b) Bonded piston seals

Bonded piston convert hydraulic pressure into linear motion. In a typical automatic transmission, pistons stroked under fluid pressure are used to actuate clutch packs that in turn engage specific gears. SKF bonded pistons feature pressure activated sealing lips that flex under pressure to retain the fluid and maintain pressure. Latest designs include a beaded lip which significantly reduce friction and hence improve operation.

c) Integrated input shaft seals

For the input shaft seal of a manual transmission, SKF has integrated additional features and functions into a solution to improve the performance. The dynamic seal is included into a unit which is bolted to the transmission, which provides static sealing to the transmission housing and optionally includes elements such as a tube to guide the movement of the clutch release bearing. These modules simplify the installation.

d) Magnetic trigger wheels

SKF is an established supplier of magnetic trigger wheels in the automotive industry with many millions being manufactured annually. The application of such magnetic trigger wheels is now extending from the initial application in the ABS brake systems into powertrain and driveline systems.

e) Output shaft seals

SKF provides shaft seals for the output shafts of all types of drive-line units including transmissions, transfer cases, Rear Drive Modules (RDM) and Power Transfer Units (PTU). Special designs are available to cope with high levels of contamination including cassette systems. Designs are also available with features to enable correct functioning with significant shaft run-out and misalignment.

f) Pinion seals for light vehicles

SKF offers pinion seals for passenger cars and light duty applications. The complete line of SKF pinion seals includes unitized designs. The unitized designs include a wear sleeve which also provides the seal running surface and a barrier to external contaminants.

With an enhanced excluder lip, radial dirt lip and primary sealing lip, SKF pinion seals provide longer service live and unmatched reliability.

g) Port seals

Port seals provide a sealed port for transferring pressurized fluid between mating housings. Pressure losses at these locations decrease hydraulic pump efficiency and transmission performance. The design of the port seal creates a flexible sealing joint that seals via axial/or radial compression or the rubber. Typical applications involve sealing hydraulic circuits within an automatic transmission.

h) Transmission front cover

The cover sealing module consists of a cover plate with an outer static seal and an inner rotary shaft seal integrated into the unit. For the typically large sizes needed at the flywheel side of a transmission, SKF has developed an economical module using assembled static and dynamic sealing elements. Here a separate shaft seal is assembled to the cover ID and an O-ring is installed on the OD.

i) Transmission input shaft seals

The input shaft of a transmission typically has the highest speeds of any shaft in the drive-line of a conventional transmission. SKF provides seals to meet this challenge with a range of sealing materials which can withstand with high speeds and associated temperatures in aggressive oils used in today’s modern transmissions.

4. Engine Seals

Today’s consumers want more power, higher fuel efficiency and a quiet, comfortable ride from a new car. Also, stringent emissions legislation requires manufacturers to increase the fuel efficiency of their vehicles, challenging them to make better use of alternate fuels (such as bio diesel and E85) and non-conventional technologies.

To meet these demands, SKF offers a wide range of engine seals, providing optimized performance for automotive applications. Our extensive testing capabilities enable us to provide advanced and reliable products. SKF shaft seals are available for engine crankshafts and camshafts as well as for auxiliary units.

a) Cassette shaft seals for heavy duty

The input shaft of a transmission typically has the highest speeds of any shaft in the drive-line of a conventional transmission. SKF provides seals to meet this challenge with a range of sealing materials which can withstand with high speeds and associated temperatures in aggressive oils used in today’s modern transmissions.

b) Elastomeric shaft seals

Rotating shaft seals offers optimum performance for automotive applications.

SKF offers a wide range of elastomeric shaft seals. Our extensive testing capabilities allow us to provide superior and reliable product on the market.

c) Injector and spark plug tube seals

Static seals for sealing spark plug, solenoids or injectors with a high degree of static misalignment. Thanks to involving engine design, to improve horsepower and efficiency, this passion of the spark plug or the in injector has been optimized to the top of the combustion chamber

d) Magnetic trigger wheels

SKF is an established supplier of magnetic trigger wheels in the automotive industry with many millions being manufactured annually. The application of such magnetic trigger wheels is now extending from the initial application in the ABS brake systems into powertrain and driveline systems.

e) PTFE shaft seals

Crankshaft and camshaft seals in PTFE material with low friction design offers high performance and durability.

PTFE radial shaft seals utilize a polytetrafluoroethylean wafer for dynamic sealing. SKF offers a range of solutions with a bonded PTFE wafer and optional unitized designs.

f) SKF Low Friction Engine Seals

Rotating elastomeric shaft seal offering high durability and low friction. SKF Low Friction Engine seals are based on the technology of the PTFE seals, but use sophisticated elastomer materials. This seals can incorporated into a sealing solutions and modules

g) SKF Rotostat integrated crankshaft seal

The intelligent combination of dynamic and static seal bonded directly to a metal carrier or retainer with an integrated engine management sensor and trigger wheels.

h) Valve stem seals

Rotating shaft seals offers optimum performance for automotive applications. SKF offers a wide range of elastomeric shaft seals. Our extensive testing capabilities allow us to provide superior and reliable product on the market.

i) High pressure valve stem seals

In addition to conventional valve stem seals, SKF has developed a new generation of valve stem seals for high pressure applications. These seals improve the quality of emissions and enhance engine operation by withstanding high pressures in the exhaust and intake ports of the engine, while maintaining their primary function as an oil metering device.

5. SteEring Seals

With power steering system the driver needs to provide only modest effort on the steering wheel, regardless of roads conditions. Many power steering applications use high-pressure hydraulic systems where seals are critical components, playing an important role in preventing pressure loss.

SKF power steering seals retain steering fluid in high-pressure applications while allowing for reduced friction in the various parts of a power steering unit. SKF expertise and extensive production experience enables us to create advanced steering seal designs for traditional hydraulic and fuel efficient electric steering systems.

a) Power steering seals

In order to minimize vehicle power losses and fuel consumption, there is strong movement away from hydraulic power steering to electrically driven systems. SKF supplies dynamic seals to all these systems using robust low noise solutions with low friction. In the hydraulic systems, we provide the seals for the rack, input shaft and pinion as well as for the pump. In the electric systems we provide motor shaft seals.

6. Suspension seals

Suspension systems serve a dual purpose: contributing to the vehicles’ road holding and braking capacity, and keeping occupants comfortable and reasonably isolated from road noise, bumps, and vibrations.

The main area for sealing in the suspension system is within the shock absorber. SKF provides sealing solutions to increase service life and reduce friction.

a) Fork seals for motorcycles and bicycles

The feel of riding and durability are two decisive factors when designing seals for forks in motorcycles and bicycles. Especially in off-road applications, such as enduro or motocross, the requirements on the sealing are very demanding.

b) Shock absorber seals

The dynamic seals are a critical for the reliable operation and life of shock absorbers.

SKF provides a range of advanced shock absorber seal solutions for all types of applications ranging from motorcycles through cars and light trucks to heavy duty commercial vehicles. The seals use specially developed materials and designs to minimize friction and prevent contamination from entering the system.

7. Wheel end Seals

Seals in wheel bearings are key in determining the life of the unit. If the seal allows external contaminants to enter the bearing or lubricant to escape from the bearing, then premature failure of the unit will result. SKF wheel end seals providing oil and grease sealing offer enhanced performance in a wide range of temperatures and fluid environments, performance and longer life under virtually all driving and road conditions.

a) Axle seals

SKF provides a full range of shaft seals for axle applications. For car and light truck as well as for heavy duty commercial vehicles. In their exposed locations beneath the vehicle, contamination exclusion is key to a long seal life and SKF offers a range of solutions addressing this issue.

b) Hub bearing unit seals for heavy duty vehicles

As a major force in the bearings market, SKF is uniquely situated to understand the requirements for sealing wheel bearing units for heavy duty vehicles and to translate these into advanced solutions.

c) Hub bearing unit seals for light vehicles

As expert in bearing and seals, SKF is uniquely situated to understand the requirements for sealing wheel bearing units for cars and to translate these into advanced solutions. SKF seals use advance materials and sealing lip designs to provide both low friction and excellent contamination exclusion which results in longer service life.

d) Hub caps

For heavy duty commercial vehicles, the hub cap provides the final seal of the wheel bearing to the outside environment. SKF has a range of hub caps engineered to protect the components of the bearing over an extended life.

A variety of additional features such as an oil level window or pre-assembled bolts are designed to make life easier on assembly and in operation.

Industrial seals

Being the world’s only bearing company with seal manufacturing capabilities, SKF supplies a wide range of sealing solutions for rotating, reciprocating and static applications to industries worldwide. Innovative sealing solutions help customers to increase productivity and process reliability as well as to reduce Total Cost of Ownership.

1. Power transmission seals

SKF’s offer of radial and axial shaft sealing solutions for power transmission applications supports virtually every industrial sector, from large-size wind turbines to very small, high-speed machine tools. For off-highway applications, SKF offers undercarriage sealing solutions for wheeled equipment, which include SKF Mudblock cassette seals and the innovative SKF Trackstar seals for tracked machinery.

2. Hydraulic seals

Hydraulic cylinder seals are used to seal the opening between various components in the hydraulic cylinder.

3. Fluid Handling Seals

SKF’s offer of radial and axial shaft sealing solutions for power transmission applications supports virtually every industrial sector, from large-size wind turbines to very small, high-speed machine tools. For off-highway applications, SKF offers undercarriage sealing solutions for wheeled equipment, which include SKF Mudblock cassette seals and the innovative SKF Trackstar seals for tracked machinery.

4. Machined Seals

SKF is the global market and technology leader in high quality custom engineered sealing solutions offering a comprehensive range of machined seals for many industries.

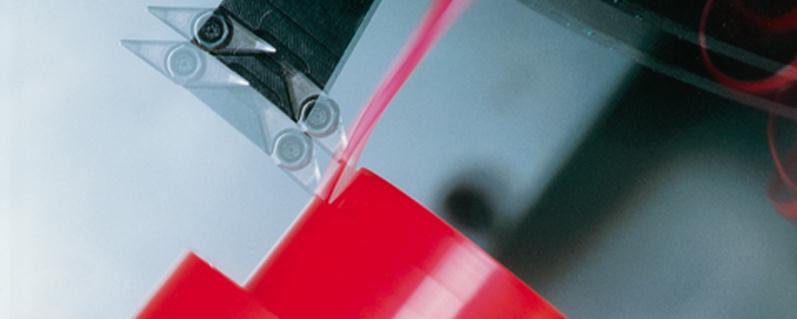

The innovative production system - SKF SEAL JET - reduces manufacturing and dispatch time to a minimum. Virtually any kind of seal for any conceivable application, in any dimension and design, can be produced.

Seal Jet Machines

The SKF SEAL JET system includes:

- Computer Numerical Control (CNC) production system

- High-precision cutting tools optimized for polymeric materials and high performance sealing materials for innovative seals production

- State-of-the-art software with up to 169 pre-programmed seal profiles

Advantages of the SKF SEAL JET system:

- Production of sealing solutions for most industries tailor-made to your customer's needs

- Prompt manufacturing of seals and components up to 600 mm in diameter

- Short delivery times

- A wide range of seal designs

- Application engineering support